Health and Safety

Health and safety is fundamental to SCA’s operations. SCA has a zero-accident vision and safety in the workplace is highly prioritized.

Employee health and safety target achieved

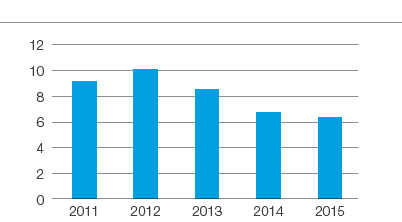

Accident Frequency Rate (FR)

The accident frequency rate declined by 6% in 2015. Compared with 2011, the decline was 31%.

The accident frequency rate declined by 6% to 6.3 (6.7) in 2015. In particular, statistics improved for the American tissue mills, partly due to joint ventures closing the gap in standards compared with other SCA companies.

Already in 2014, SCA achieved its target to reduce its accident frequency rate by 25% in the 2011–2016 period. In the 2011–2015 period, the accident frequency rated fell by 31%. As a consequence, SCA has adopted a new ambitious health and safety target with the aim to reduce the accident frequency rate by 50% in the 2014–2020 period.

SCA also updated its OHSAS 18001 target, see OHSAS 18001 certification below.

No fatalities were reported for the third consecutive year.

Safety policy and governance

OHSAS 18001 certified sites

Ten main sites were certified under OHSAS during 2015. A main site is defined as a production site wholly owned by SCA with 100 or more employees.

SCA has a Group Health and Safety Policy and the Group’s governance system encompasses risk assessment, training, targets and monitoring in the safety sphere. There are health and safety committees on which representatives of about 94% (96) of the workforce serve. 78% (74) of employees are covered by formal trade union agreements in which health and safety issues are addressed on a regular basis. In addition, a reference team has been in place since 2009 with responsibility for coordinating Group health and safety matters. All SCA facilities have procedures in place to increase workplace safety.

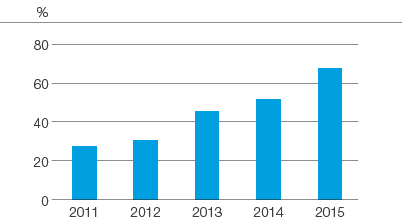

OHSAS 18001 certification

SCA implements the international OHSAS 18001 (Occupational Health and Safety Assessment Series) standard to ensure that uniform processes are deployed across the Group, and that SCA units continuously improve their workplace health and safety. OHSAS specifies requirements for an organization’s occupational health and safety management systems. In 2015, SCA updated its OHSAS 18001 target, stating that all fully-owned and joint operations will be OHSAS 18001 certified by 2020. At the end of 2015, 68% (52) of SCA’s 65 main sites were certified.

Group-wide key performance indicators

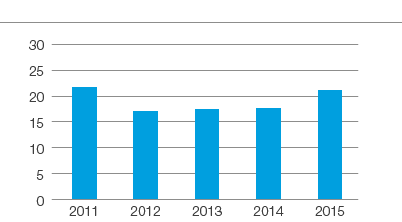

Accident Severity Rate (ASR)

The accident severity rate rose in 2015, a common consequence when the frequency rate declines.

In recent years, SCA has worked intensively to systematize and improve its safety work. SCA uses the following Group-wide KPIs:

- Number of Lost Time Accidents (LTA): accidents that result in an employee missing the next regularly scheduled work day or shift.

- Days Lost due to Accidents (DLA): number of work days lost due to an LTA.

- Accident Severity Rate (ASR): The DLA / LTA.

- Frequency Rate (FR): LTA / 1,000,000 hours worked.

- Incident Rate (IR): LTA / 200.000 hours worked.

- Number of fatalities.

|

2015 |

2014 |

Lost Time Accidents (LTA) |

360 |

375 |

Days Lost due to Accidents (DLA) |

7,545 |

6,546 |

Accident Severity Rate (ASR) |

21.0 |

17.5 |

Frequency Rate (FR) |

6.3 |

6.7 |

Incident Rate (IR) |

1.3 |

1.3 |

Fatalities |

0 |

0 |

During the year, 76 accidents (51) were reported among contractors.

Near miss/risk reporting

Reliable near miss and accident reporting is key; it is vital to analyze both serious and less serious occurrences to ensure that they are not repeated.

SCA has a reporting system for accidents and risk observation in place. Employees use it to report accidents and close calls, meaning events that could have led to an accident. The system significantly improves SCA’s ability to perform risk assessments, analyze and improve working methods, and continuously monitor performance.

In the event of a critical incident, information is communicated to the entire Group, enabling all units to gain access to the recommendations and learn from the occurrence. Another part of the unit procedures involves gathering data from the reporting system on a weekly basis so that safety can be addressed at staff meetings. The system also allows for best practices to be disseminated throughout the Group.

Since the introduction of the system several years ago, it has been noted that, to all appearances, many LTAs are the result of trivial causes. For example, accidents may be caused by slips, trips and falls of a less serious nature, which should be preventable. It was also observed that some units need to increase their focus on manual work and ergonomics.

Zero-accident sites

19 sites reported zero accidents in 2015: Logistics Lübeck and Witzenhausen, Germany; Pune, India; Altopascio, Italy; Monterrey and Uruapan, Mexico; Suameer, the Netherlands; Svetogorsk/Kamennogorsk and Veniov, Russia; Gemerská Hôrka, Slovakia; Telde, Spain; BM Skandinavien Stugun and Norrplant/Bogrundet, Sweden; Chesterfield, Manchester, Oakenholt and Welshpool, UK; Bowling Green and Greenwich, US

Joint industry action

Health and safety risks in the pulp and paper industry tend to be higher than those in the engineering industry. Therefore, SCA’s forestry operations participate in several industry collaboration projects to promote safety.

A working group focusing on occupational health and safety has been formed within the Swedish Forest Industries Federation. The objective is to support the safety programs of member companies by offering various resources for raising awareness and sharing knowledge.

Another valuable contribution is being made by the SSG (Standard Solutions Group) safety committee, through which companies in the pulp industry come together to learn from one another. SSG sets technical standards and recommendations and provides information and advice.

Healthy workplaces

SCA also works proactively with employee health and well-being. Each business unit is responsible for formulating a structure for fitness that suits their own operations. SCA’s efforts encompass measures such as better ergonomics, quit-smoking campaigns, dietary training, support in work-life balance and advice in handling difficult illnesses.

Since 2008, SCA’s North American operation has had a health program that includes encouraging a healthy lifestyle and regular, voluntary health check-ups, as well as early identification of health risks. The European hygiene operations prioritize efforts for improving its employees’ lifestyle and health, particularly when older employees are concerned. The goal is good health, fewer sick days and higher productivity.

In addition to promoting health and safety at its sites, SCA checks suppliers’ practices and collaborate with them to improve safety performance.

Health and safety at the workplace was also further addressed in SCA’s awareness campaign, the Global Safety Week, see chapter Health and Safety.