Combatting climate change

SCA is working in many ways to reduce its climate impact. In addition to managing forests that absorb CO2, SCA is also working to reduce the CO2 emissions generated by its operations and investing in the production of renewable energy, such as biofuels and wind power.

SCA is making significant investments in new technology, including an investment in the Östrand pulp mill in Timrå, Sweden, and an investment in a biofuel facility in Nokia, Finland. SCA is also taking many small steps by continuously implementing small improvements to make our work better and more efficient, for example, through the ESAVE energy-saving program.

Our forests absorb a net amount of 2.6 million tons of CO2 each year, which is more than the emissions generated by SCA’s production operations. Forests also play a key role in our efforts to increase the availability of renewable energy. Raw material and by-products are converted into biofuels, thereby becoming valuable energy. Our forest land is also an important foundation for our wind power projects.

TARGET

We will reduce CO2 emissions from fossil fuels and from purchased electricity and heating by 20% by 2020, with 2005 as the reference year.

We will triple our production of biofuels from our forests by 2020, with 2010 as reference year.

The production of wind power on SCA forest land will increase to 5 TWh by 2020.

OUTCOME 2015

At the end of 2015, CO2 emissions in relation to production levels had declined 17.4%, compared with the reference year of 2005.

SCA’s production of biofuel from its own forests amounted to 610 GWh (687).

Wind energy from SCA forest land was 1.9 TWh (1.1).

New technology makes waste valuable

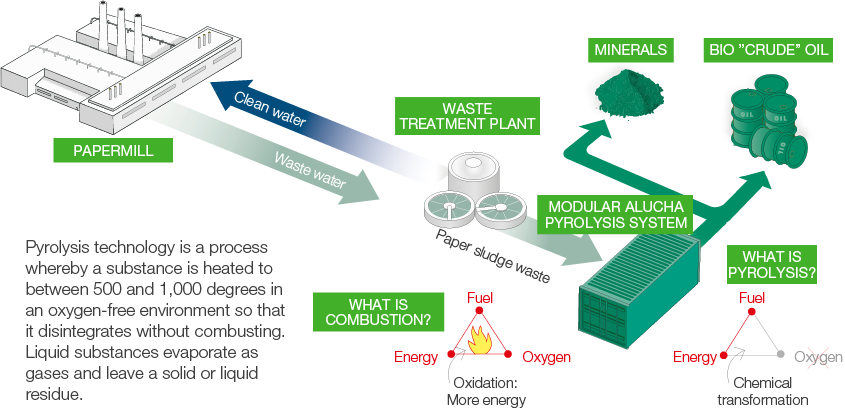

Together with external partners in the Netherlands, SCA is pioneering the use of pyrolysis technology to extract energy from sludge. The technology has huge potential to reduce waste and carbon emissions. SCA will also save money by converting waste into carbon-neutral energy and minerals that can be sold as raw materials.

In 2015, SCA developed a reactor specifically designed for sludge pyrolysis.

“All fiber is converted to fuel in the reactor, while other materials (minerals) are recycled,” says Tom Berben, Director of Environmental Compliance.

SCA’s partners in the project are the resources and innovation company Alucha, and the University of Twente in the Netherlands.

“In 2016, we will build a 150 kg-per-hour mobile unit that we will bring to our European and US mills for pilot testing.”

The pilot tests at SCA’s mills will help the company to design full-size industrial installations from 2017.

New Finnish biofuel plant

set to reduce costs and carbon emissions

In cooperation with local partners, SCA is investing in a new biofuel power plant in Nokia, Finland, that will provide SCA’s tissue paper mill in Nokia with a low-cost, renewable and reliable energy supply. The plant will also reduce carbon emissions by almost 40%, equivalent to 20,000 tons per year.

“The project is on schedule and on budget. “The biofuel plant will start producing steam in April 2016, and we expect SCA’s investment to be repaid within four years through reduced energy costs,” explains Heikki Mustaniemi, Manager of the Nokia tissue paper mill.

The biofuel plant will meet most of the paper mill’s steam requirements, and provide all heating at the SCA facility. The project will therefore significantly reduce dependence on natural gas.

The plant will mainly be fueled by locally sourced woodchips, but there are plans to combust all the biosludge from SCA’s Nokia mill in the future. The biosludge is currently disposed of as a waste product.

“The project really is win-win – for the environment, and for our business,” says Mustaniemi.

40% reduction in carbon emissions, corresponding to 20,000 tons per year

World-class pulp

Work on the Östrand project began in February 2016 with a 12 meter concrete pile being driven into the ground.

The demand for pulp is growing. By doubling the pulp production of the Östrand pulp mill, not only will SCA become one of the largest producers of bleached softwood sulphate pulp in the world, the plant will also become state-of-the-art in terms of quality and the environment.

This industrial investment is one of Sweden’s largest ever. In August 2015, SCA announced that it would invest SEK 7.8bn in its pulp mill outside of Timrå. The investment will boost the mill’s competitiveness and create a world-class cost position.

The environmental performance of the new plant will be high and energy efficiency will rise significantly. Östrand is a major producer of energy and will double its deliveries of green electricity to about 1,000 GWh.

The investment will also have a major positive impact on the local community by creating of a large number of jobs. In the long term, some 500 to 600 people will be employed in forest management and the raw-material transportation chain. A further 120 jobs will be created to distribute the doubled pulp volumes to customers. Several thousand individuals are expected to be employed by contractors during the three-year construction period in connection with the expansion. As many as 2,000 people will be working simultaneously on expansion and production.

By-products become biodiesel

SCA has decided to build a pilot facility for the production of biodiesel and chemicals at its kraftliner mill in Obbola. The fuel and chemicals will be produced from black liquor, a by-product of pulp production that is currently burned in a soda recovery boiler. The black liquor is refined into lignin oil, which in turn is processed into biofuel and chemicals.

Biofuel can be sold to oil companies, for example, as an almost completely renewable raw material. One example is renewable diesel, which has the potential to fully or partly replace fossil diesel in normal diesel vehicles.

The pilot facility is expected to be built in 2016 and become operational in 2017. The facility will be unique since the pulp mill and the biorefinery will be integrated.

New smart pellets

+20%

increased energy per unit volume

SCA is investing in the development of black pellets, which are expected to make a commercial breakthrough. This new bio-based product has the potential to replace fossil coal in many applications.

Black pellets are made from biomass roasted at a very high temperature in an oxygen-free environment, resulting in pellets that contain 20% more energy per volume unit than traditional white pellets.

Black pellets offer many advantages. They make transport more efficient, are easier to grind and can be handled outside – even when it is raining – without absorbing water.

Black pellets are a climate-smart alternative for areas that currently use various types of fossil coal, for example, in emerging markets such as China. SCA is investing in black pellets through a partnership with BioEndev, which is building a demo facility in Holmsund.

Growing forests are good for the climate

At the United Nation’s climate-change conference in Paris, COP21, the 195 participating nations concluded a first-ever global climate deal with the aim of keeping the global temperature rise to “well below 2 degrees Celsius.”

Kersti Strandqvist, SCA’s SVP Group Sustainability, participated in a panel debate held by the World Business Council for Sustainable Development (WBCSD), with a focus on how business can make a contribution to combatting climate change. She presented how SCA’s model of managing forests responsibly and replacing energy-intensive products with forest-based products, are two of the most effective ways to combat climate change.

“What this means specifically is that 6 billion tons of CO2, which is equivalent to 15% of our global greenhouse gas emissions, can be prevented annually by investing less than USD 20 per ton of CO2.”

SCA’s hygiene products also contribute to meeting the emissions target. The development of innovative new products and services is based on a life cycle perspective, which means looking at their environmental impact across their entire life cycle – a cradle-to-grave approach – and working with resource efficiency in all phases. SCA is also working with its suppliers to develop new materials with better performance and lower environmental impact.