Climate and energy

SCA’s efforts to reduce its climate impact and energy use are manifested through numerous projects, investments and modifications of processes, all of which contribute individually to the target of reducing CO2 emissions.

Major investments

Investments in new technologies and upgrades to existing solutions play a significant role in SCA’s ability to achieve its CO2 target. In January 2015, a new lime kiln was put into operation at the kraftliner mill in Munksund, Sweden. Unlike its predecessor, the new kiln is fueled with pellets instead of oil. This shift will reduce the mill’s annual fossil CO2 emissions by 20,000 tons, or 75%, and cut costs by SEK 50m per year.

SCA has invested SEK 380m and Sundsvall Energi SEK 100m in the BioCoop energy project, thereby increasing deliveries of energy from SCA’s mills to the Sundsvall district heating grid and reducing oil consumption. The project involved the redesign and conversion of two boilers at Ortviken paper mill, enabling them to be fueled with wood pellets, and connecting Östrand pulp mill to the Sundsvall district heating grid. The new boilers reduce carbon emissions by approximately 25,000 tons.

The company’s investments in a biofuel plant in Nokia, Finland, and in pyrolys technology in the Netherlands are described in chapter Climate and energy.

ESAVE

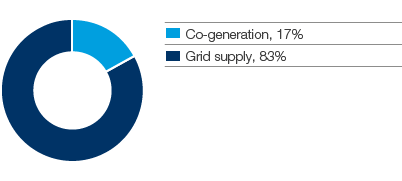

Electricity consumption 2015

Electricity consumption 2015: 8,036 GWh

The majority of SCA’s electricity, 83%, comes from national grids, while 17% derives from electricity produced in the Group’s co-generation plants.

Since 2003, SCA’s ESAVE energy-efficiency program has contributed to energy savings and improved efficiency in all operative business units. In 2010, SCA adopted a target for ESAVE: to reduce energy consumption per ton of product produced by 14% by 2020. In 2015, 110 ESAVE projects were implemented, resulting in a 0.5% (3.2) reduction in energy used per ton of product produced. The accumulated energy savings in the 2010–2015 period amounted to 8.2%, corresponding to a 1.6 TWh reduction in energy consumption.

ESAVE encompasses investments in energy-efficient technical solutions, the involvement of employees in daily improvement activities and a general change in attitude toward the use of energy at SCA. Knowledge sharing is leveraged across the company through training and network events and ESAVE is part of the onboarding program for several young engineers. A typical ESAVE project could involve reducing electricity consumption by improving or replacing pumps, compressors, fans or lighting. Experiences are documented and provide effective support for future improvement efforts.

Transport

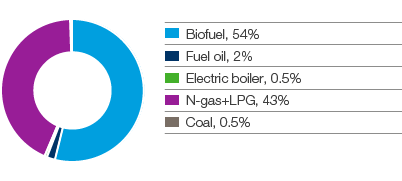

Fuel consumption 2015

Fuel consumption 2015: 60,252 TJ

A total of 43% of SCA’s fuel consumption comes from natural gas and 54% from biofuel. Oil and coal account for a mere 2% and 0.5%, respectively.

SCA monitors the environmental impact of its transport activities and is working on a broad front to reduce emissions. These efforts include increasing the fill ratio, applying various techniques to reduce fuel consumption, prioritizing transport means with less environmental impact, reducing distances travelled and strengthening purchasing procedures. The Group’s total carbon emissions from transport activities in 2015 amounted to 0.87 million tons (0.87).

Shipping

Shipping accounts for 71% of SCA’s total transport activities. The Group’s three roll-on roll-off (RoRo) vessels cover about 10% of its shipping needs, with a total freight capacity of about one million tons.

A new regulation from the UN’s International Maritime Organization was implemented as of January 2015. This new regulation reduces the permissible sulphur content in marine fuels from 1.0% to 0.1% in defined regions. SCA’s vessels have been adapted for the use of low-sulphur fuel. The new regulation increased the Group’s fuel costs by approximately SEK 68.5m in 2015.

Road transport

23% of SCA’s freight is transported by road. SCA engages in a number of collaboration projects to cut transport emissions, including tests of vehicles using biomass-based fuels. In 2015, SCA in Germany joined the non-profit logistics initiative Lean & Green to achieve a 20% reduction in carbon emissions within logistics by 2018. SCA in BeNeLux and Italy committed to the initiative in 2009 and 2014, respectively. The action plan includes consideration of pallet height and loading, combined transport, double-deck trucks and strategic planning, such as localization of production and warehouses.

SCA is one of the nine companies in France that has signed a charter called FREIGHT21 with The Ministry of Sustainable Development on May 20, 2015 in order to reduce its CO2 emissions from (mainly road) transportation. Some of the means to achieve SCA’s commitment to reduce emission by 5% include increasing volumes, reducing distances and the number of trips, and greater use of rail transport.

Rail transport

Rail transport accounts for 6% of SCA’s total freight – this small share is partially due to restrictions in the rail network. Because rail transport is a carbon-efficient alternative, it is a prioritized transport means. SCA uses multimodal transport for distances exceeding 1,000 km. If there is no direct rail connection, SCA requests that its suppliers use rail to the greatest extent possible, supplemented by truck transport. If there is no, or a very small, price difference between alternatives, SCA will choose the solution with the least impact on the environment.

Business travel divestment

During 2015, SCA announced that the company, together with the other part-owners, was divesting Bromma Business Jet. The transaction gave rise to a cost of approximately SEK 95m, which was reported as an item affecting comparability in 2015.

The EU Emissions Trading Scheme (ETS)

SCA had 32 mills and plants included under the ETS in 2015. SCA’s operations in the Nordic region will continue to produce a surplus, while its operations in the rest of Europe will have a certain deficit. This balance provides an estimated average annual surplus of about 200,000 tons of carbon dioxide equivalents during the third phase of ETS. The surplus is the result of the measures implemented by SCA over an extended period in the form of energy-saving activities, process optimization, choice of fuel and major investments, such as a new lime kiln in Munksund in Sweden and a new biomass boiler in Nokia, Finland. The average market price for emission rights in 2015 was about EUR 7.6 per ton and SCA sold 410,000 emission rights.