Comprehensive climate work

SCA is working in many ways to reduce its climate impact. We continuously work with energy efficiency and to reduce the climate impact of our products. We invest in the production of renewable energy, such as biofuels and wind power. Our forests also net absorb 4.1 million tons of CO2.

Reductions in climate impact are mainly through larger investments in facilities or by continuously making our work slightly better and slightly more efficient, for example, through the ESAVE energy-saving program (see chapter Climate and energy). We take our products’ entire lifecycle into consideration to minimize their impact as much as possible.

Our forests absorbed 4.1 million tons of CO2 in 2016, which is more than SCA’s emissions from its entire production. Forests also play a key role in our efforts to increase the availability of renewable energy. Raw material and by-products are converted into biofuels, thereby becoming valuable energy. Our forest land is also an important foundation for our wind power projects.

TARGET

We will reduce CO2 emissions from fossil fuels and from purchased electricity and heating by 20% by 2020, with 2005 as reference year.

We will triple our production of biofuels from our forests by 2020, with 2010 as the reference year.

The production of wind power on SCA forest land will increase to 5 TWh by 2020.

740

Gwh

SCA’s production of biofuel from its own forests amounted to 740 GWh.

Minimized product impact

Tork Smartone reduces paper consumption by up to 40%.

Reducing climate impact is not only about investing in new production technology. Equally important is a reduction in the product’s impact and, through this, to contribute to the UN’s Sustainable Development Goal 12 for sustainable consumption.

Since the beginning of the 1990s, SCA has worked with life cycle assessments, which involve a complete environmental analysis of a product’s value chain, from raw material, production and transport to use and waste management. Our hygiene products have reduced their carbon footprint in recent years (see chapter People and nature innovations and chapter Customers and Consumers) and SCA continues to work with resource-efficient products and new services for customers.

Designing products that cut consumption is an effective way to reduce the climate impact. The Tork XPressnap dispenser is designed so consumers can only take one napkin at a time and we guarantee a 25% reduction in napkin consumption. Tork SmartOne is another example that offers a reduction in tissue consumption by 40%. TENA Solutions is a service through which we can help nursing homes to optimize their incontinence care through an extensive analysis of operations. The result is improved well-being for care recipients, less waste and lower total cost.

Reduced emissions and costs through more efficient power production

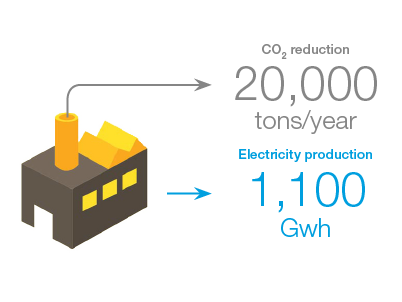

SCA’s upgrade of the biodigester in Mannheim will reduce carbon emissions and increase production efficiency.

SCA is upgrading the biomass boiler at its tissue plant in Mannheim, Germany. Biomass is a waste product from the production of tissue and the 1,100 GWh produced here makes Mannheim the Group’s second largest power facility.

SCA is upgrading and replacing large parts of its biomass boiler in order to comply with the Industrial Emissions Directive, IED. The upgrade requires a EUR 10m investment and has several advantages. The boiler is expected to be 10% more efficient with new components and new technology. Carbon dioxide emissions are also expected to fall by about 20,000 tons at the same time as operating costs are reduced by EUR 4m per year. The biomass boiler upgrade is scheduled to be complete in late 2017.

Doubling of green electricity

The expansion of the Östrand pulp mill is one of the largest ever industrial investments in Sweden.

The multi-million SEK investment in SCA’s pulp mill in Östrand, Sweden, will make it the world’s largest producer of bleached softwood sulfate pulp and will more than double its production capacity, from 430,000 to 900,000 tons. The SEK 7.8bn investment makes the expansion one of the largest ever industrial investments in Sweden.

Construction began immediately after approval of the investment in August 2015, and is scheduled to take three years to complete. The new wood house will be completed first and will begin operating during the second quarter of 2017.

The investment means SCA will supply products of world-class quality and environmental performance. We can also offer pulp bleached using the latest techniques (ECF and TCF) produced using raw materials from responsible forestry. In addition, the plant will be fitted with the latest technology to increase energy efficiency and minimize emissions to air and water.

Finally, Östrand will more than double its deliveries of green electricity and district heating to 1.2 TWh electricity per year, which is sufficient to provide electricity for 240,000 households.

SCA’s pulp mill in Östrand will double its production capacity, from 430,000 to 900,000 tons and double its deliveries of green electricity and district heating to 1.2 TWh.

Fuel from the forest

Fill the tank with trees? Anders Hultgren illustrates the principles behind the production of biofuels from by-products in pulp manufacturing.

Black liquor, a by-product from pulp manufacturing, will be made into renewable gasoline and diesel when SCA’s pilot plant in Obbola near Umeå begins operating early in 2017. SCA is the first company to use a technology that enables the production of biofuel from the lignin contained in black liquor.

Simply put, this means copying nature: “What took nature 100 million years to create, SCA can achieve directly using by-products from the forest industry,” explains Anders Hultgren, Development Manager at SCA.

The manufacturing process is reminiscent of what happens at oil refineries. It is therefore possible to manufacture other petrochemical products, such as raw materials for the production of plastics and pharmaceuticals.

All of this offers access to a new market which is in principle insatiable – the world needs an enormous amount of energy. Customers of the future for SCA’s new product could be oil companies, distributors or bus companies. One major advantage is that vehicles and filling stations and other infrastructure do not need to be rebuilt or replaced, which means substantial savings in time and money.

“Our new product also increases the value of the pulp mill, which can increase production as we get better at utilizing by-products. And in a wider perspective, this transfer from fossil to renewable means we are contributing to solving global warming,” says Anders Hultgren.

The goal is large-scale fuel production, but before SCA can make a decision on a continuation, the pilot plant must be completed, begin operating and be evaluated. If everything runs smoothly, it may be interesting for other pulp plants, in Sweden and in the rest of the world.

Renewable energy equivalent to household electricity for

220,000

houses.*

Scandinavia’s largest wind power area inaugurated

The Björkhöjden and Ögonfägnaden wind farms in northern Sweden were inaugurated on June 1. The wind farms comprise 123 wind turbines in total.

Together with the Stamåsen wind farm, Björkhöjden and Ögonfägnaden form the largest wind power area in Scandinavia. The wind farms will generate the equivalent of 1% of Sweden’s total energy consumption, or household electricity for 220,000* houses or 560,000* apartments.

The wind farms, which are located in the municipalities of Ragunda, Sollefteå and Strömsund, were inaugurated with the theme “Wind Farm for the People”. Approximately 850 participants were served with food and coffee and offered guided tours, music and a performance by the vaudeville group Karneval.

The wind farms are operated by Statkraft SCA Vind, a joint venture where Statkraft owns 60% and SCA 40%. Statkraft is responsible for financing the wind farms and SCA for the land.

* Source Statkraft.se